Boiler Blowdown System Manufacturers, Suppliers in India

Boiler Blowdown Control System in India

Welcome to the Manufacturers, Suppliers of Boiler Blow Down System in India. We are providing Boiler Blow Down Control System in India for the applications like Industrial Boiler, Steam Generation Plants, Heating System, Process Industries etc.Contact us now for the Boiler Blow Down System/Boiler Blow Down control System/Boiler Blow Down Valve Manufacturer in India | Volfram Systems India Pvt. Ltd.

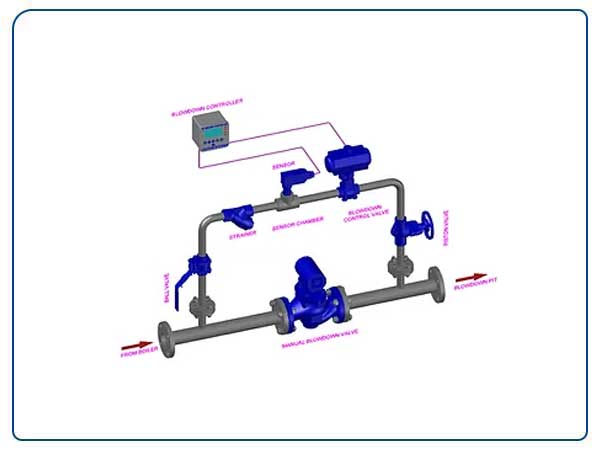

Boiler Blow Down System Manufacturers, suppliers, exporters in India. Volfram Systems Maintaining water quality in industrial boilers is of prime importance for efficiency, safety, and longevity. Maintaining water quality In industrial boilers is of prime importance for efficiency, safety, and longevity. The main function of Boiler Blow Down Systems is that it effectively manages the concentration of dissolved and suspended solids in boiler water in the industries.

We Volfram provide Engineering Solutions for a Changing World. We have been serving the Steam System industry since a decade. Our purpose is to export Boiler Blow Down System that are built for bright and secure future for everyone involved in our business. Boiler Blow Down System manufacturers strive to give excellent customer services in India. To deliver an outstanding, sustainable, efficient Boiler Blow Down System to our customers our experts designs innovating and improved versions of Boiler Blow Down System in India.

What is Boiler Blow Down System?

Boiler Blow Down System manufacturers supplies Boiler Blow Down System for removing impurities and contaminants from water. The Boiler Blow Down System are specially designed for making the water free of impurities and contaminants, that maintains optimal operation and longevity of the boiler.

Boiler Blow Down System key functions:

- Reduce Concentration of Impurities: Boiler Blow Down System helps to maintain the desired levels of dissolved and suspended solids, By the mechanism of occasionally draining a portion of the boiler water.

- Prevent Scale Build-Up: Boiler Blow Down System Prevent Scale Build-Up which is accumulated by Continuous operation of the boiler. In the steam system accumulation of scale and deposits occurs, which can reduce heat transfer efficiency in the system.

- Control Boiler Water Chemistry: The Control Boiler Water Chemistry means it controls proper blow down, ensuring the chemical constitution of the boiler water remains less than acceptable limits which minimizes corrosion and extends the equipment life.

- Manage TDS Levels: Over a time in the boiler Total Dissolved Solids (TDS) can accumulate which leads to operational issues in the steam system. The Boiler Blow Down System manufactured by Volfram manages control of TDS levels by effectively removing high-concentration water.

Why chose us?

Volfram Systems India Pvt. Ltd. are leading Boiler Blow Down System manufacturers in India. We are the best choice for your business needs of Boiler Blow Down valve because:

- Our Expertise: With 12 years of experience in the Steam system industry, we strive to deliver our best in manufacturing Boiler Blow Down System in Maharashtra.

- Customization of Boiler Blow Down System: To meet customer’s requirement of Boiler Blow Down System we offer custom options that provides optimal performance and efficiency.

- Quality Boiler Blow Down System Products: We Boiler Blow Down System supplier provides high quality products that are designed by our engineers delivering reliability and longevity.

- Technical Support: Through all the process like installment, repair spare services our Technical team supports the customers for seamless and hassle-free experience.

Boiler Blow Down System Types

We Volfram, Boiler Blow Down Valve Manufacturers provides a wide range of Boiler Blow Down System in India:

Continuous Blow Down System

- Operation: For maintaining the expected water chemistry, a small quantity of boiler water is continuously discharge by Continuous Blow Down System.

- Advantages: It helps , minimize the risk of boiler scaling and corrosion by ensuring in line control of TDS levels.

- Applications: Finds application in boilers where high steam generation rates are there. Continuous Blow Down System are important in quality control of water.

Intermittent Blow Down System

- Operation: Intermittent Blow Down System includes periodic or occasional manual or automatic discharge of boiler water on basis of few preset parameters.

- Advantages: They are appropriate for boilers with variable steam demand, that allows accurate control over blow down frequency and volume in the Boiler Blow Down System.

- Applications: Intermittent Blow Down System are use where smaller boilers are installed, such as where continuous blow down may not be practical.

Volfram’s Guide on STEPS INVOLVED in SELECTION of Boiler Blow Down System

- Assessment of Boiler Operation: First operating conditions, steam generation rates should be evaluated. And water quality requirements are checked.

- Determine Blow Down Rate: The required blow down rate is calculated based on factors such as boiler capacity, steam demand, water chemistry.

- Select Blow Down Control Method: Here continuous or intermittent blow down are choose. This is selected based on the required water quality goals and operational needs.

- Consider System Integration: Check for the compatibility of Boiler Blow Down System with the existing one, that is boiler control systems. Also check for integration capabilities.

- Evaluate Maintenance Requirements: For minimizing downtime and operational disruptions in the system the Assess to maintenance and servicing facilities should be checked. And we Volfram provide all these services.

Specifications

| Sr. No. | Specifications | Details |

|---|---|---|

| 01 | Material | We only use high quality materials and corrosion-resistant materials for manufacturing Boiler Blow Down System such as Stainless steel, carbon steel. |

| 02 | Pressure Rating | We designs Boiler Blow Down System that are mostly Compatible with boiler operating pressure and temperature in the system. |

| 03 | Blow Down Rate | For specific water quality targets, we provide Adjustable blow down rate options in the Boiler Blow Down System. |

| 04 | Control System | We Boiler Blow Down System suppliers provide both Manual or automatic control options that also has features like monitoring and alarm features. |

| 05 | Installation | As per the requirement vertical or horizontal mounting are provided in the Boiler Blow Down valve that utilizes space properly. |

Applications of Boiler Blow Down System

- Industrial Boilers: Boiler Blow Down System are used in power generation processes, in chemical processing units, food & beverage industries and also at healthcare facilities.

- Steam Generation Plants: Boiler Blow Down System are Important in maintaining water quality such as in steam generation plants that includes cogeneration and combined cycle plants.

- Heating System: They are suitable in commercial and residential heating systems for efficient operation and longevity of boilers.

- Process Industries: Industries like textiles and paper, pharmaceuticals etc. uses Boiler Blow Down System.

A well-designed Boiler Blow Down System Manufacturer in India are Volfram Systems. Boiler Blow Down System Exporters provides efficiently working and sustainable products for steam systems. We Boiler Blow Down valve suppliers focus of delivery of Boiler Blow Down System to customers that meet their expectations and provides customer satisfaction. We: Volfram are your trusted partner for all your requirement of boiler blow down system in India.

Contact us and get your Boiler Blow Down System. We are waiting to serve you and assist you regarding your queries on Boiler Blow Down System.