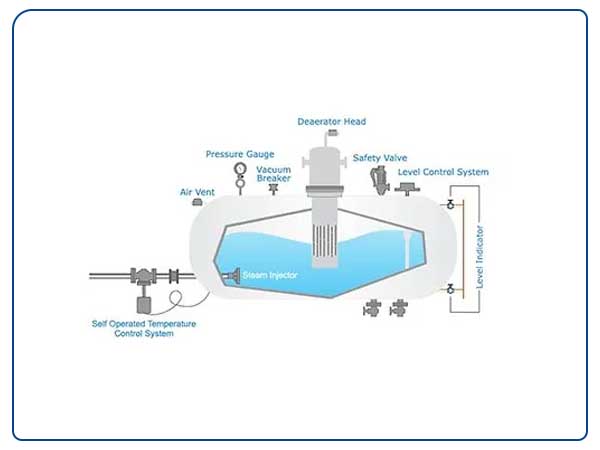

We offer fully equipped Feed water tank for Boiler, designed to maintain various parameters of feed water, required to run the boiler safely & efficiently.

We provide complete package of feed water tank of various capacities with the proper automation to maintain the optimum level & temperature in feed water tank.

Enquiry Now

Deaerator Head

Oxygen or other incondensable gases in the steam system can restrict the heat transfer to the process as well as causes corrosion in the steam & condensate system.

So it is very important to remove the oxygen & other gases from the steam system or to ensure that these gases do not get into the steam system. This can be done by thermal deaeration.

The removal of the gases is achieved by maintaining the highest possible temperature in the feed water tank from where these gases can enter into steam system. We offer specially designed deaerator heads to suit customer's requirement.

Steam Injection System

We offer complete solution for the direct steam injection system for the feed water tank to maintain the required temperature in the feed water tank.

The system consists of Self Operated Pressure control & Temperature control Valves, steam injector, vacuum breaker. The required temperature can be set easily on the temperature control valve.

Level Control System

Maintaining the optimum level in the feed water tank is very important in order to ensure maximum temperature in feed water tank from condensate recovery & ensure the safety of the boiler.

To achieve this without manual intervention, level control system is used. We offer a customized Level Control Systems for Boiler Feed water tank where hot condensate is preferred & utilized maximum, then hot water from any other sources & last preference to the cold make up water.

This ensures that the energy of hot condensate & hot water from other sources is utilized.

Enquiry Now