Ball Float Steam Trap Manufacturers in India, Ball Float Steam Trap Suppliers, Exporters in India

Ball Float Steam Trap in India/Ball Float Steam Trap Manufacturers India

We Offering Ball Float Steam Trap in India. As we are Manufacturers, Suppliers, Exportetrs of Ball Float Steam Trap in India | Volfram Systems India Pvt. Ltd.

We are Ball Float Steam Trap Manufacturers, Suppliers, Exporters in India. We are providing Ball Float Steam Trap in India for the applications like in industrial processes such as refineries, chemical plants and food processing units Ball Float Steam Traps are widely used. Contact us now for the Mechanical Steam Trap Manufacturers/Ball Float Steam Trap Manufacturers in India | Volfram Systems India Pvt. Ltd.

We are Ball Float Steam Trap manufacturers in India are the trusted Ball Float Steam Trap suppliers, Exporters in India serving the steam industry since 12 years. The Mechanical Steam Trap manufacturers in India work on the principle of buoyancy. Basically they take advantage of difference in density of condensate and steam for discharging the condensate. Ball Float Steam Trap, inverted bucket traps are few example of Mechanical Steam Traps.

We are also Ball Float Steam Traps Manufacturers in India. The Ball Float Steam Traps removes condensate and air while preventing the loss of steam from the steam system. We are reputable manufacturer of Ball Float Steam Traps which is a type of Mechanical Steam Traps providing several benefits. It helps in energy saving, maintaining steam quality. They enhance the lifespan of steam system components by incorporating Ball Float Steam Traps by preventing the corrosion and water hammering. We Ball Float Steam Traps manufacturers provide reliability and long service life.

Features of Ball Float Steam

- High Capacity: Ball float steam traps are suitable for handling large capacities of condensate and find application in high-volume.

- Immediate Response: Ball float steam traps maintain control over steam pressure, they quickly react to changes in condensate level.

- Energy Efficiency: Ball float steam traps minimize steam loss, that makes them energy efficient, also reduces reducing operational costs.

- Durability: Ball float steam traps by Volfram operate under a wide range of pressures and temperatures due to its strong structure.

Specifications

| Sr. No. | Specifications | Details |

|---|---|---|

| 01 | Sizes | 15 NB, 20 NB, 25 NB, 40 NB, 50 NB, 65 NB |

| 02 | Available Class / Rating | #150 |

| 03 | End Connection | Socket Weld or Screwed & Flanged Ends |

| 04 | Maximum Operating Pressure | 19.37 Kg/cm2 @ 30°C |

| 05 | Maximum Operating Temperature | 450°C @ 4.69 Kg/cm2 |

The Application of Ball Float Steam Trap

- In industrial processes such as refineries, chemical plants and food processing units Ball Float Steam Traps are widely used.

- Our Ball Float Steam Traps manufacturers provide Steam Distribution system with Ball Float Steam Traps for efficient removal of condensate.

- In HVAC Systems Ball Float Steam Traps removes condensate from steam coils and heat exchangers.

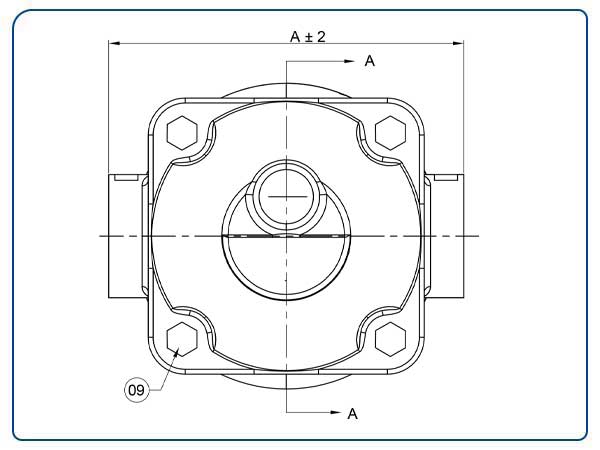

VOLFRAM FOFT 20 Ball Float Steam Trap with internal air vent) are designed for draining condensate from all types of low and medium pressure steam heating and process equipment.

Typical applications include unit heaters, heat exchangers, driers and jacketed vessels.

CI Ball Float Steam Trap

FOFT 20 - 4.5, FOFT 20 - 10, FOFT 20 - 14, Option with SLR / AV Thermostatic

Available Spares

- Valve Seat

- Ball Float and Level Assembly

- Air vent Assembly

Features

- Discharges condensate at saturated temperature

- Excellent air venting (by thermostatic air vent)

Limiting Conditions

- PMO: Max. operating pressure 14 bar(g)

- TMO: Max. operating temperature 220 ºC

- Cold hydro test pressure 21 bar(g)

- Sizes: NPS 1/2, 3/4, 1.

- Connections: Screwed (NPT/BSPT/BSP)

Installations

The trap should be installed below the drain point of the equipment in a position so what the float arm is in a horizontal plane and the float rises and falls vertically, with the flow direction as indicated on the body.